Bunta's Initial B

Z250SL ARACER full computer setup

The Z250SL’s engine has been tuned by Suzuka Porting, the same company that worked on the Ninja 400.

That said, no aftermarket parts are used and the tuning is done using only genuine parts.

However, since there are limitations to setting up the stock ECU, we installed an aftermarket ECU called ARACER, which is a “full computer,” and set it up.

I’m only a little more than an amateur when it comes to engine control, so I often have to take the long way around and get through it with sheer determination.

I’m trying my best to make it into an engine I like, little by little.

Well, as an amateur, I’ve summarized what’s happened so far. Please read it.

ARACER already contains data compatible with normal engines, and the setup will be based on that data.

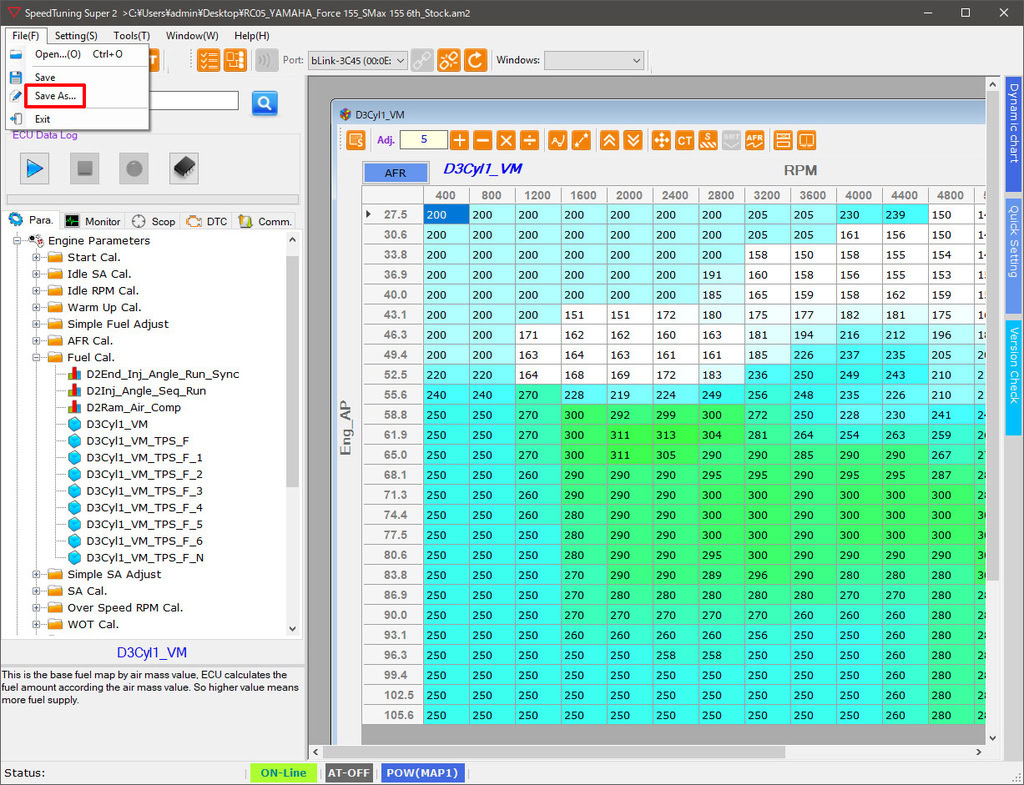

The image on your computer will look like this:

This ARACER data is for a standard engine, so it will need to be significantly changed.

ARACER has a function that uses log data from actual driving to semi-auto tune and get closer to the ideal air-fuel ratio.

The air-fuel ratio of the entire map is now almost perfect, and the engine is now burning in good conditions.

In fact, this is where the real challenge of setting up for competition begins.

Our goal is to create an engine that is rider-friendly, delivers the power desired wherever it is desired, and responds directly to the rider’s controls.

My Z250SL has a lot of engine potential, so I have a 4-cylinder long final drive in the rear. In addition, the tires are 150 size.

In reality, it’s probably 5 to 6 teeth longer. “The purpose of this change is to change the vehicle balance by changing the axle position.”

If this happens, the engine will drop too much when making figure eight turns, spinning, or making short turns, which are typical of gymkhana, making the bike very difficult to handle.

It’s to the point where you start to wonder if the engine will stall and stop.

If possible, I would like to run without using the clutch, so I am currently working hard to get the engine set up so that I can run without using the clutch.

We’ve come up with a pretty good solution with the fuel mixture and ignition timing, but it’s quite difficult to change the engine’s characteristics.

Tuned engines are especially difficult to run at low speeds.

Therefore, by changing the injection timing, which was also effective with the Ninja 400, we will create an engine that is a little different.

Injection timing is exactly what it sounds like: when to inject fuel.

Injection bikes usually inject fuel into the intake manifold.

Fuel is injected while the intake valve is closed, and injection ends while the valve is still closed.

The air and fuel are thoroughly mixed in the heated intake manifold before the intake valve opens and the fuel enters the combustion chamber.

As an aside, “increasing fuel = the injector is open for a longer time,” so at high RPMs the time between when the intake valve closes and when it opens also becomes shorter, making it difficult to complete the injection within that time.

The fuel injection will not be able to keep up and the injector will remain open, so when this happens you will need to install a big injector.

However, the atomization ability will decrease, so you don’t want to make it as large as possible. Especially at low speeds, the engine will run poorly.

Maybe some of you remember that?

Enough with the digression though.

This injection timing has a subtle effect on control when first opening the throttle at low RPMs, especially when used in gymkhana.

This was learned with the Ninja 400, and even with Honda’s trial machines, the low-speed tenacity is controlled by changing the fuel injection timing.

I’ve seen articles like that too.

I adjusted the fuel mixture, ignition timing, injection amount when fuel is cut, acceleration pump function, and many other things to make the adjustments.

We will change the injection timing to give the engine more flavor.

But even so, I’m a bit worried about the inherent characteristics of this engine, or the way it starts to accelerate at very low speeds.

The current idle speed is 1500-1600 rpm. It’s an unstable single engine, so if I could raise it to around 2000 rpm, the stalling sensation at low speeds would be reduced.

I think that if you increase the rpm above 1600, the engine will start to malfunction.

It would be nice if we could always get the same amount of engine torque at extremely low speeds, but this aspect is still unstable.

I feel like if I try to go all the way, it’s going to cause me to fall. Which control is making me do that?

It’s going to take a bit more time to get fixed.

Now, will I be able to make it in time for the Jimuchaya Cup? I’m a bit worried, but I’ll do my best.

By the way, I’m currently driving a Q5A, and even when I push hard, there’s no lack of traction in either the front or rear, so in terms of suspension,

I think it’s in a decent condition. I’ll be changing to high-grip tires for the actual race, but the Q5A is great for working on the engine setup because it can run at room temperature.

https://ssbfactory.seesaa.net/article/503564730.html